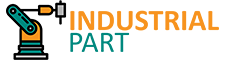

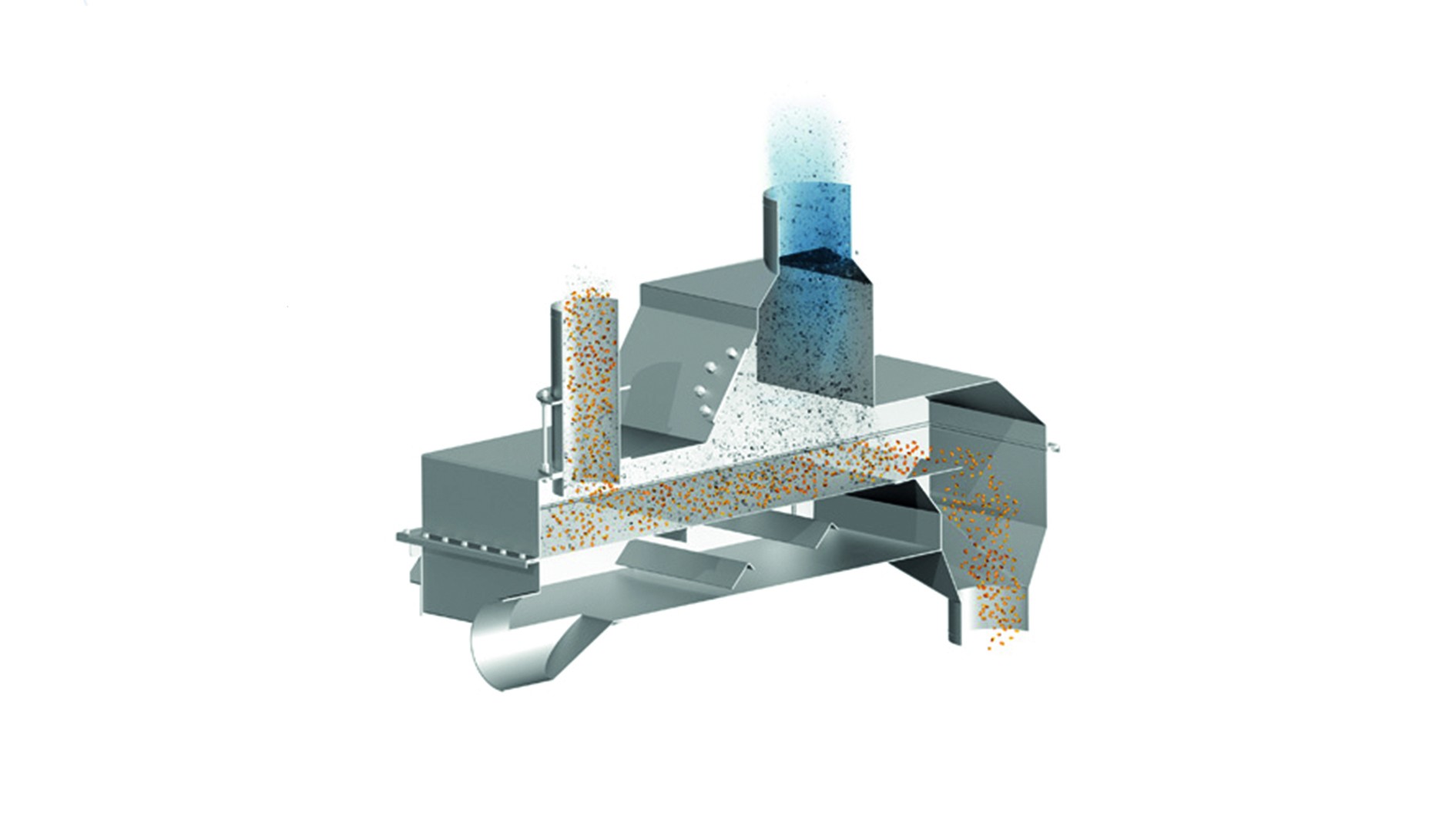

Zeppelin DS dosing and conveying screw

You can get an offer for the Zeppelin DS dosing and conveying screw product of the brand Zeppelin right now!

Zeppelin DS dosing and conveying screw Details

- Product Name: Zeppelin DS dosing and conveying screw

- Brand: Zeppelin

- Keywords: Zeppelin, , Zeppelin , , Zeppelin , , Zeppelin , DS, Zeppelin DS, DS, Zeppelin DS, DS

If you have any questions, please mail to info@industrialpart.de.

Characteristics Stainless steel pipe conveying screw with one or two outlets Available in five sizes (80/100/150/200/300). Configurations with various distances from the center of the feeding inlet to the outlet available, in 50 mm increments. All sizes generally without intermediate storage. Stainless steel feeding inlet housing standardized with welded round feeding inlet with pipe segment and outlet. Outlet has no sharp edges (flared and rounded) and is designed as a crosspiece. Can be opened for de-aeration or inspection by means of upper nozzles. Single-outlet version: Screw shaft with laser-cut screw flight, continuously welded and progressively arranged in the conveying direction Two-outlet variant: Screw shaft with laser-cut screw flights, continuously welded on both sides. Because the screw runs in reversible operation (2-outlet variant), there is only one pitch between the screw flights; the motor’s rotation direction is adjusted to the conveying direction. Bearing housing with stainless steel plate, with dust-tight external bearings and food-industry-compliant bearing lubrication, air purge bushing, PTFE joint ring and product reject slot. Lifelong lubrication of the bearings, no subsequent lubrication required. Direct operation by means of plug-in transmission motor. Output can be adjusted to local conditions (bulk material, bulk material weight, output, accuracy of weighing scale, etc.) via frequency converter to be installed by the client Conveying and dosing with high dosing precision by means of a dosing star as well as regulation using the frequency converter All surfaces that come into contact with bulk material are made from stainless steel. Processed surfaces / interior surface roughness 0.8µm, polished exterior. No sharp edges on outlet (flared and rounded) Gap-free welded helix and screw flight Flange joint on feeding inlet, flared coupling on outlet (optional) Flange joint (for flange valve or transition piece) Operating pressure and mechanical design pressure between -0.2 bar and 0.1 bar (g) Withstands temperatures between -10 and +50°C (operational and mechanical design temperature) Declaration of incorporation or declaration of conformity in accordance with the Machinery Directive, EC type examination certificate in accordance with the ATEX Directive and declaration of ATEX conformity available Equipment configurations, options and accessories Description: Trough conveying screw with one or two outlets Description: Quick cleaning EHEDG-compliant design using food-industry-compliant oils and lubricants High-quality smoothing of rough areas / electro-chemically polished surfaces Sealing gas for bearing at feeding inlet and outlet, or feeding inlet during dosing/conveying to weighing scale. Sealing gas helps to ensure long service life for the bearing Cleaning hatches and safety limit switches from size 100. Corresponding number and sizes depending on size and distance between feeding inlet and outlet. Speed monitoring sensor. Supervision of rotary frequency is recommended in explosion risk areas, in particular so that the maximum permissible circumferential speed is maintained.

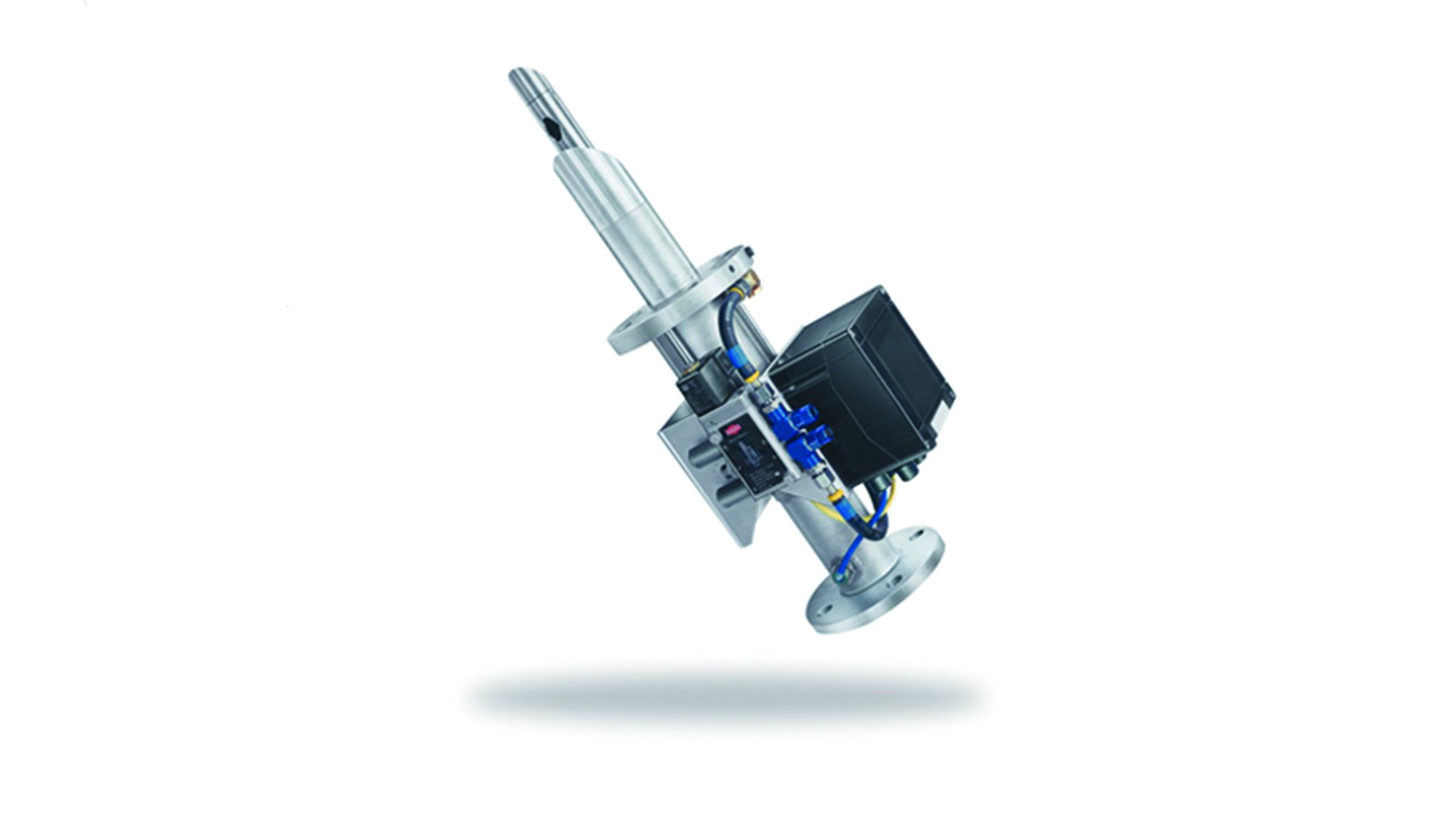

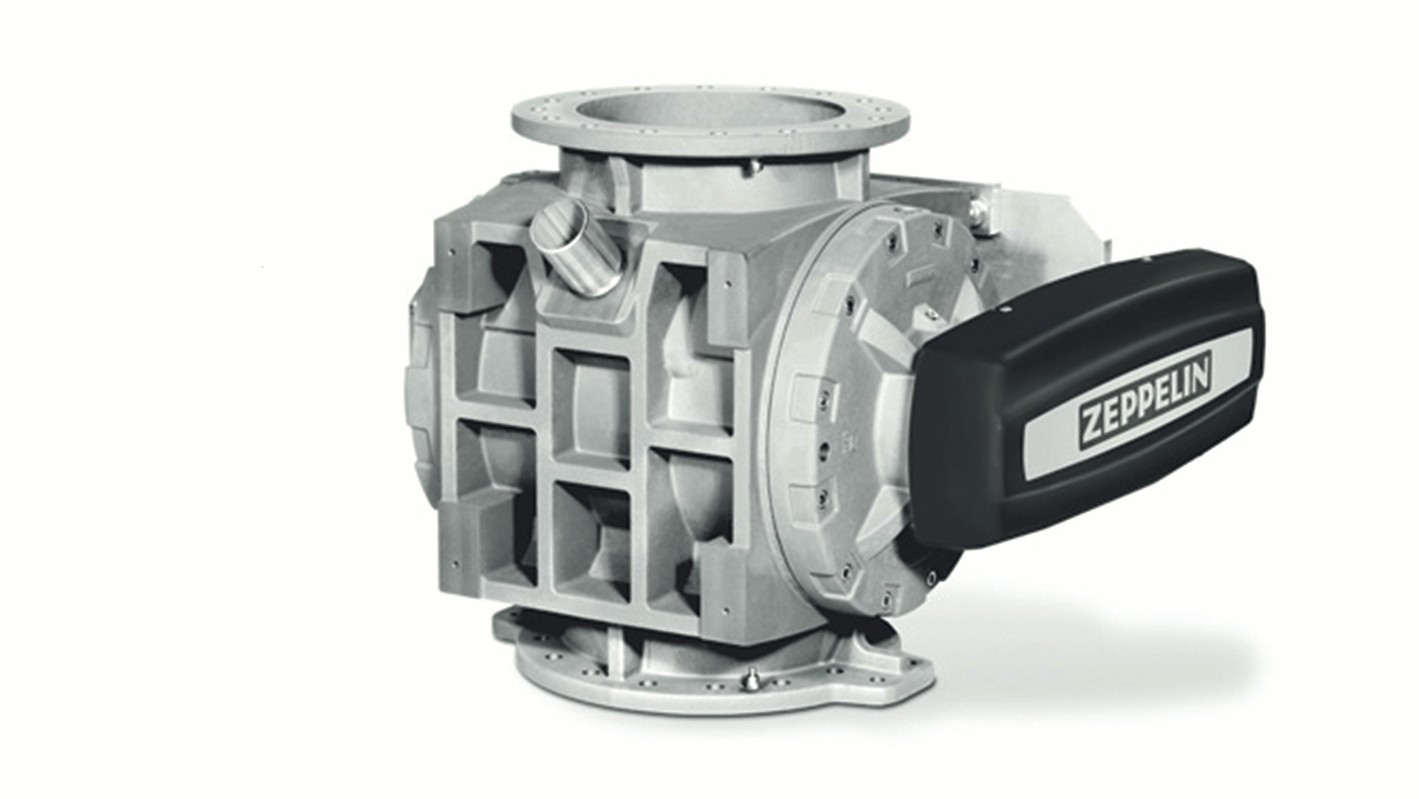

About the Zeppelin

You can contact us for all products of the brand Zeppelin. We will send you a special offer as soon as possible!