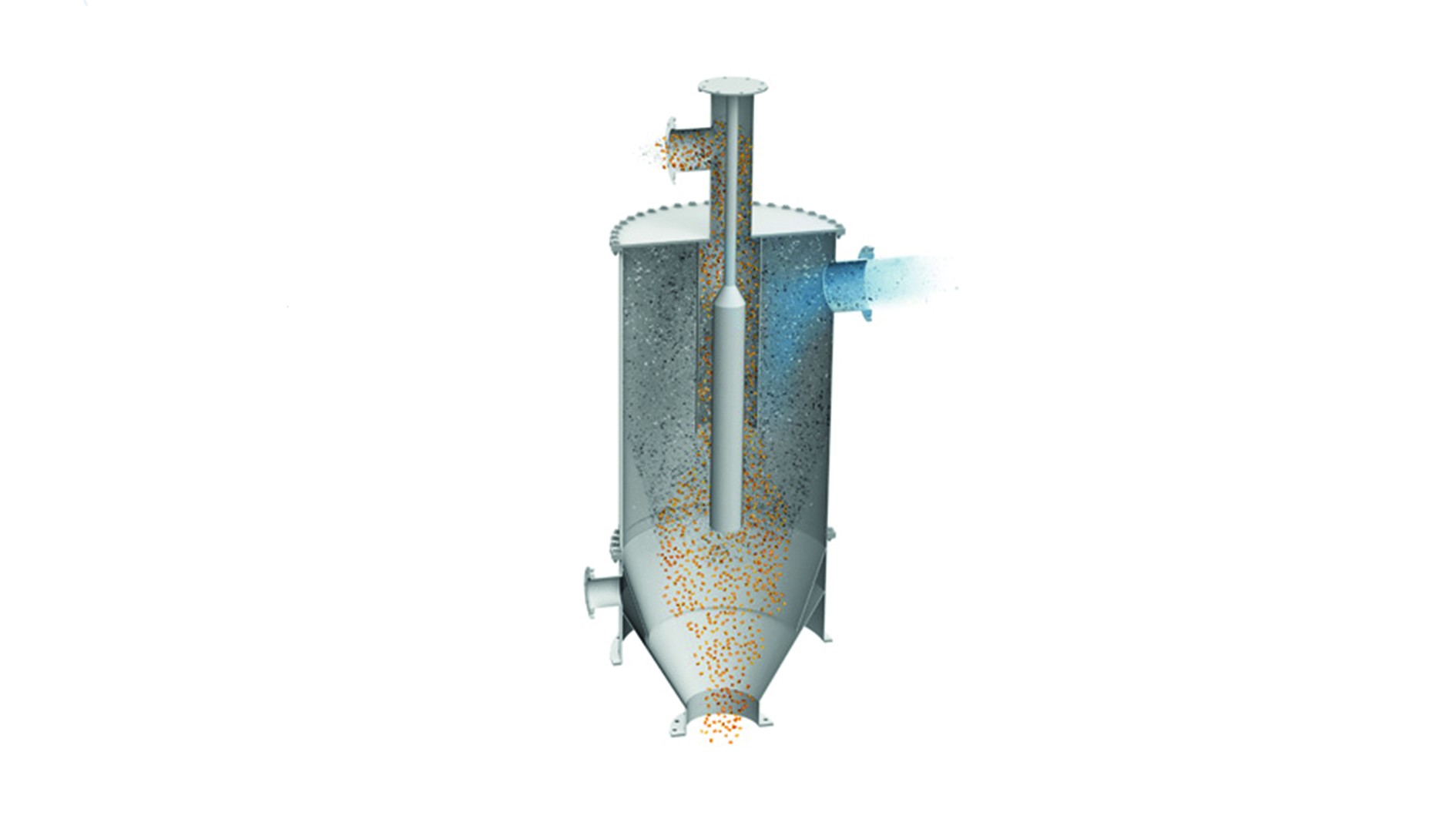

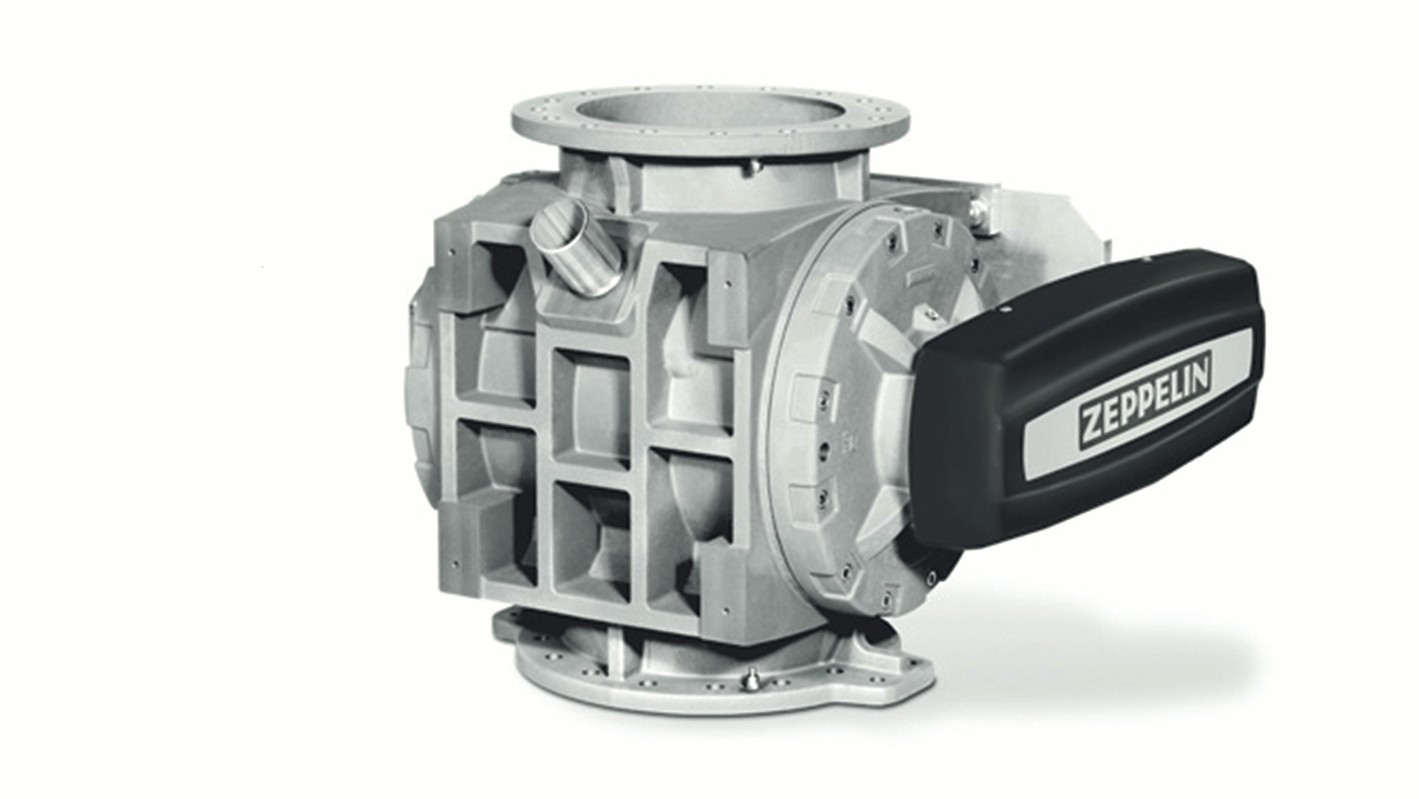

Zeppelin CFH rotary feeder

You can get an offer for the Zeppelin CFH rotary feeder product of the brand Zeppelin right now!

Zeppelin CFH rotary feeder Details

- Product Name: Zeppelin CFH rotary feeder

- Brand: Zeppelin

- Keywords: Zeppelin, CFH, Zeppelin CFH, rotary, Zeppelin rotary, CFH rotary, Zeppelin CFH rotary, feeder, Zeppelin feeder

If you have any questions, please mail to info@industrialpart.de.

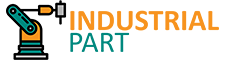

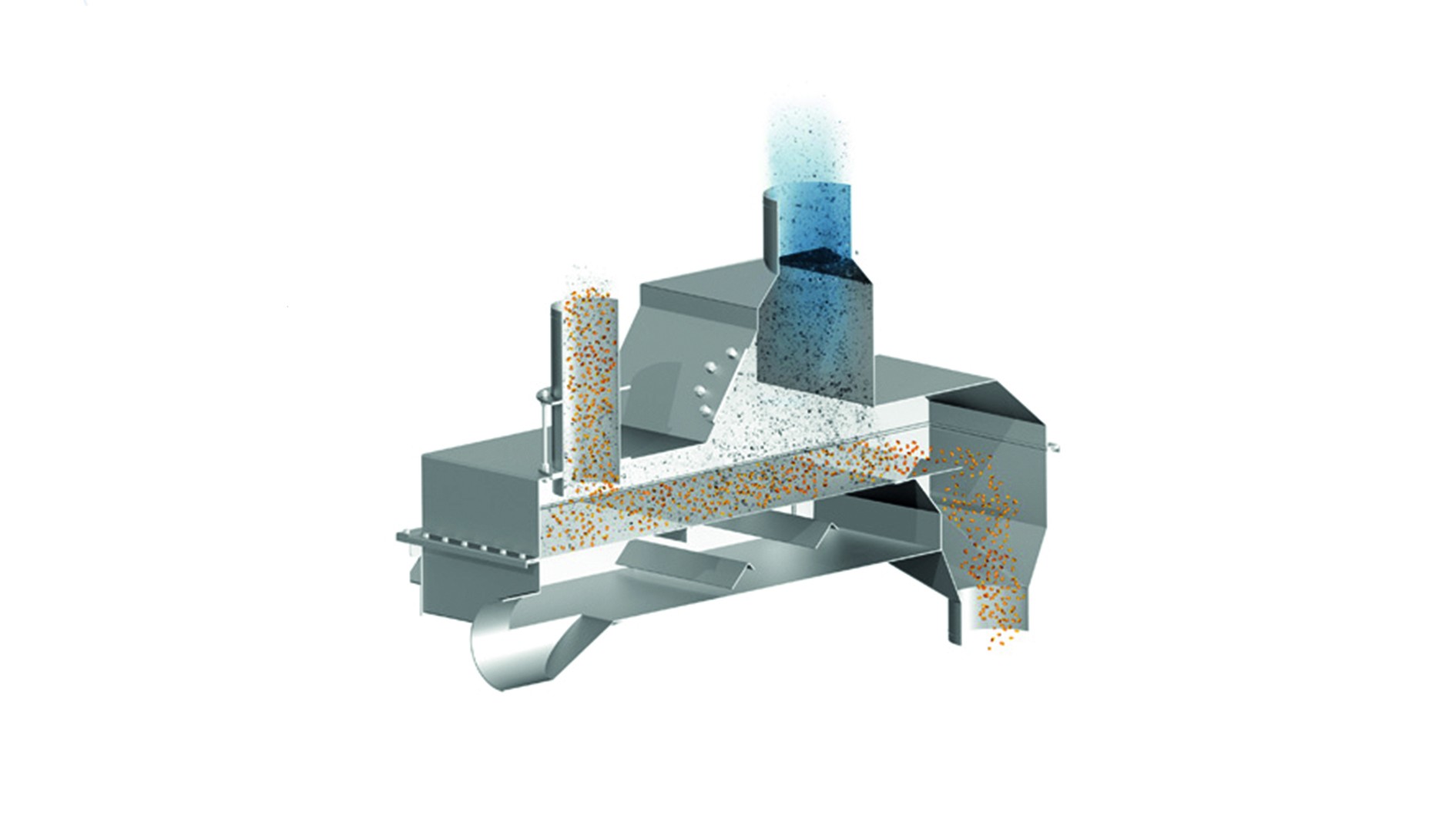

High-pressure compact feeder The CFH high-pressure rotary feeder is mainly used for the conveying and discharge of bulk material in pneumatic conveying systems. Its special design allows it to be used at differential pressures up to 3.5 bar (g), while maintaining minimal leakage values. Characteristics Extremely wide range of outputs thanks to eight available sizes (200–850) Gentle distribution of bulk material at ideal filling factors, achieved by optimized inlet and outlet geometry Minimal gas leakage due to optimal, customized spacing and side-sealed 12-chamber rotor Extremely high throughput and output, with high filling range, low overflow and integrated leakage-gas channel Durable and low-maintenance in design features and materials selection Identical housing shape for all CF valves, from powdered to pelleted bulk materials High-quality cast aluminum (hard-coated) housing and bearing plates as standard, available in high-quality cast stainless steel as an option High-quality stainless steel rotor Integrated leakage-gas nozzles in housing Permanently lubricated external rolling bearings. Reject opening between shaft-sealing rings and bearings Durable, radial, low-wear sealing system Differential pressure between up to 3.5 bar (g), mechanical design pressure from -1.0 to 10 bar (g) High mechanical temperature resistance from -20 to 90°C, optionally up to 180°C Flange joints bored in accordance with DIN 2501 PN10 FF or ANSI 150 lbs FF Declaration of incorporation or declaration of conformity in accordance with the Machinery Directive, EC type examination certificate and declaration of ATEX conformity available Equipment configurations, options and accessories: Quick cleaning Chopper function Beveled rotor Rotor chambering Sealing gas to protect bearing Rotary frequency monitoring and speed measurement Temperature control (process heating) and enclosure of housing Surface treatment and finishing Pre-metering to limit the fill level Leakage-gas container for optimal leakage-gas discharge Locking frame Pick-up shoe

About the Zeppelin

You can contact us for all products of the brand Zeppelin. We will send you a special offer as soon as possible!