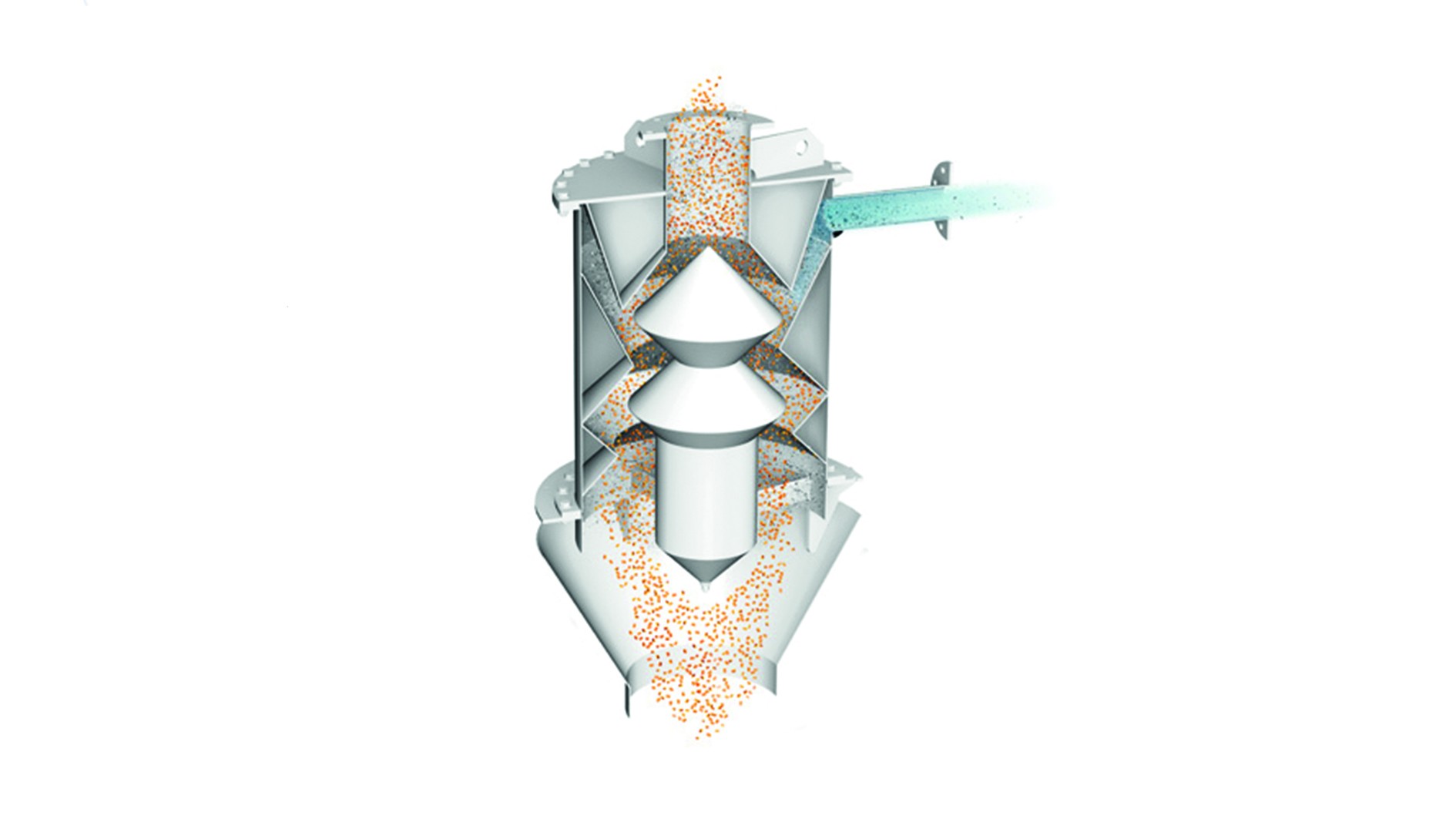

Zeppelin FB discharge bottom

You can get an offer for the Zeppelin FB discharge bottom product of the brand Zeppelin right now!

Zeppelin FB discharge bottom Details

- Product Name: Zeppelin FB discharge bottom

- Brand: Zeppelin

- Keywords: Zeppelin, FB, Zeppelin FB, discharge, Zeppelin discharge, FB discharge, Zeppelin FB discharge, bottom

If you have any questions, please mail to info@industrialpart.de.

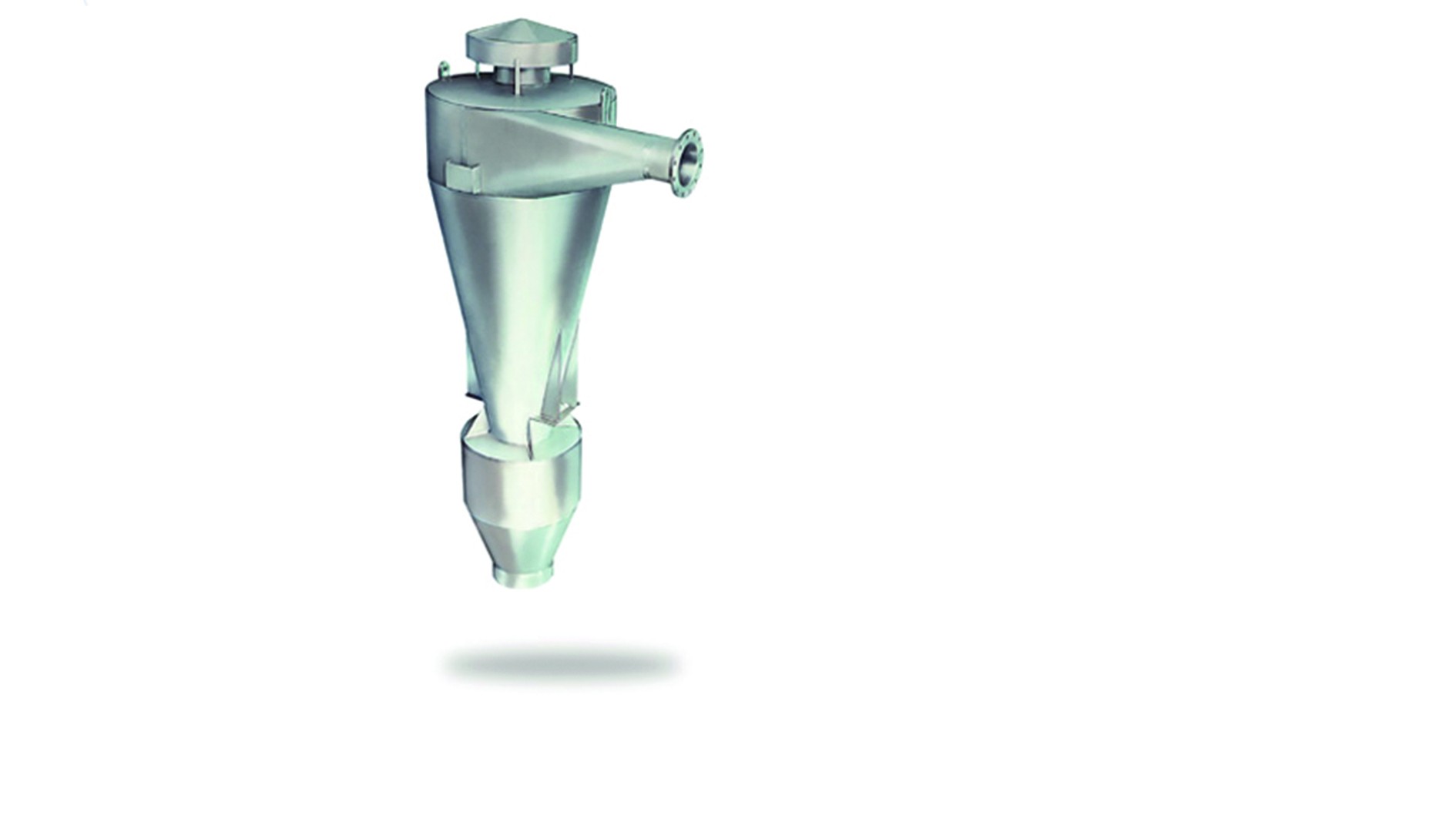

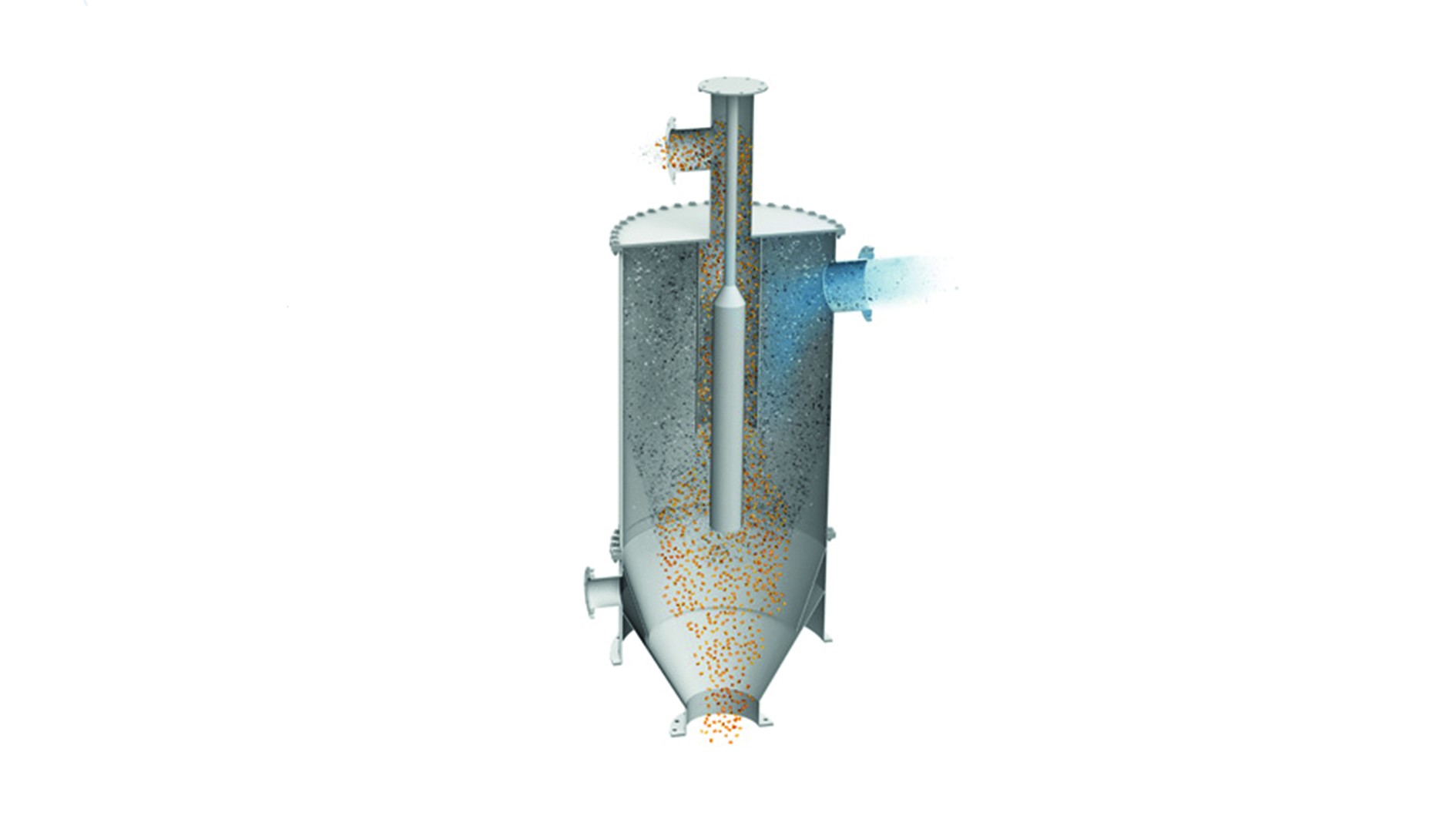

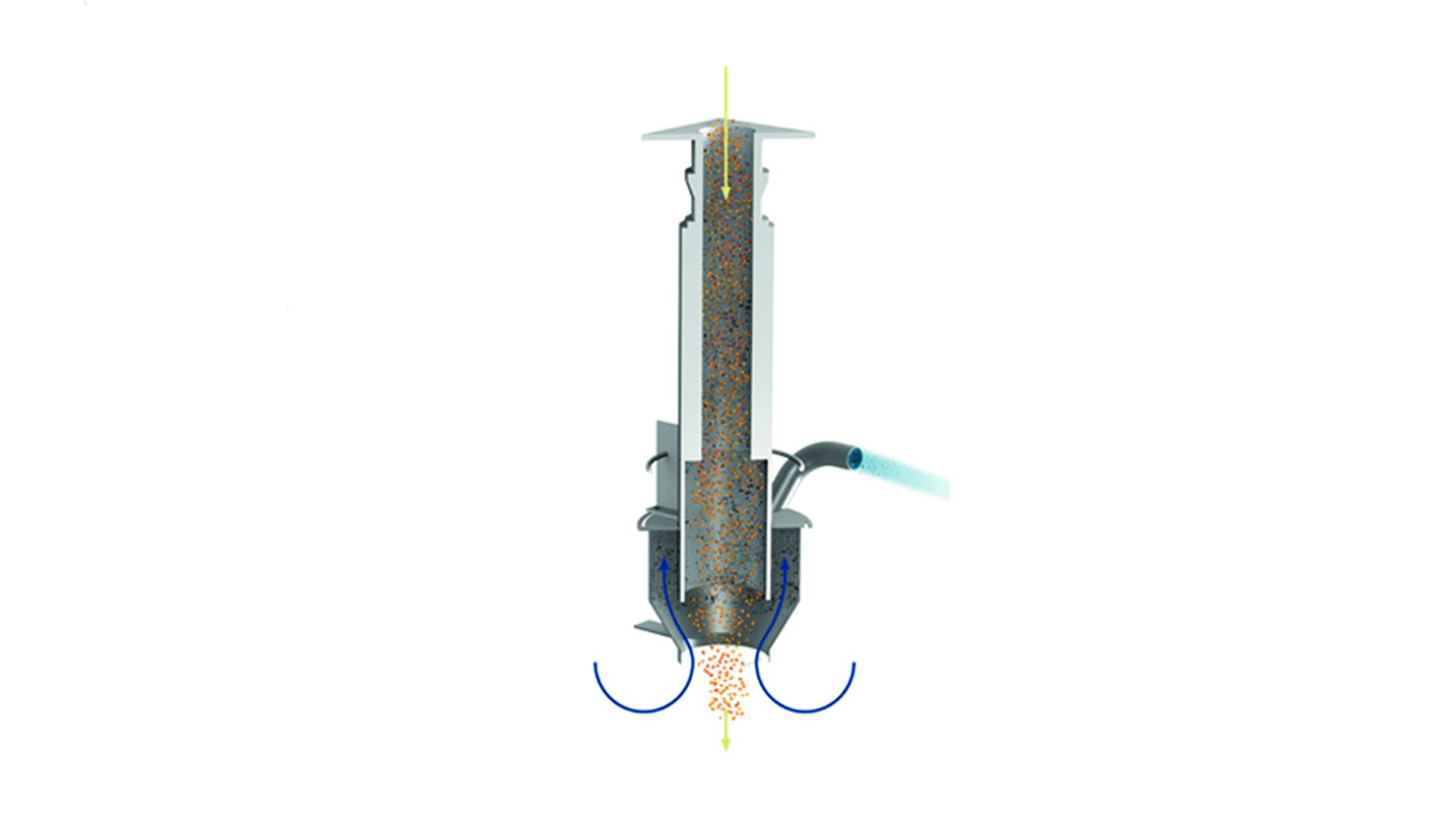

The fluidizing bed can be installed onto cylindrical exterior or interior storage silos, as well as weighing and storage containers, using a bored mating flange (container must be vented to the atmosphere). The product outlet is directly connected to the downstream unit, creating a tight, closed system. The fluidizing bed also offers further applications: Mixing, drying, temperature control, recrystallization. Allow our experts to advise you so you can implement an engineering design that is tailored to your specific application. Characteristics Output that is gentle on bulk materials, by means of pneumatic activation of the bulk material column Bulk material fluidizing allows for even/pulsation-free output Optimized gas consumption plus maximum discharge capacity Optimized structural arrangement of chambers allows for (virtually) residue-free discharge Wide range of applications such as fluidizing, discharging, mixing, drying and temperature control are all covered by a single product Durable and low-maintenance Gas distribution funnel with aeration base featuring injection nozzle, inlet and outlet flange Upper cone opening with flange coupling for connection to container, lower cone opening with flange joint for rotary valve, conveying screw, gutter, sealing caps or other conveyors Cone with optimized number of chambers depending on size and application Funnel gradient of 60° or 110° depending on application and installation situation Robust design adapted to silo load and contents External cone in powder-coated steel or stainless steel Aeration base made from polyethylene sintered plates, also available in stainless steel sintered plates if required for your application (sintered stainless steel) Stainless steel terminal strip No dead space Temperature resistance between -10° and 70°C (operational and mechanical design temperature) ATEX-compliant Equipment configurations, options and accessories: Can be operated as an aeration unit with process gas reservoir including accessories (60° funnel gradient) or with aeration unit for compact blower (110° funnel gradient) Pipe fittings and pipe system

About the Zeppelin

You can contact us for all products of the brand Zeppelin. We will send you a special offer as soon as possible!