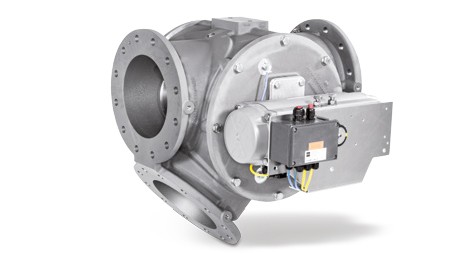

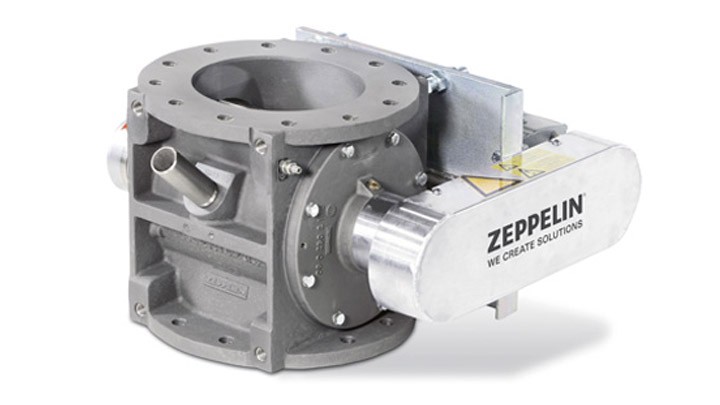

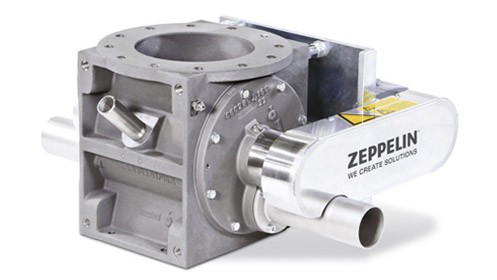

Zeppelin VB discharge bottom

You can get an offer for the Zeppelin VB discharge bottom product of the brand Zeppelin right now!

Zeppelin VB discharge bottom Details

- Product Name: Zeppelin VB discharge bottom

- Brand: Zeppelin

- Keywords: Zeppelin, VB, Zeppelin VB, discharge, Zeppelin discharge, VB discharge, Zeppelin VB discharge, bottom

If you have any questions, please mail to info@industrialpart.de.

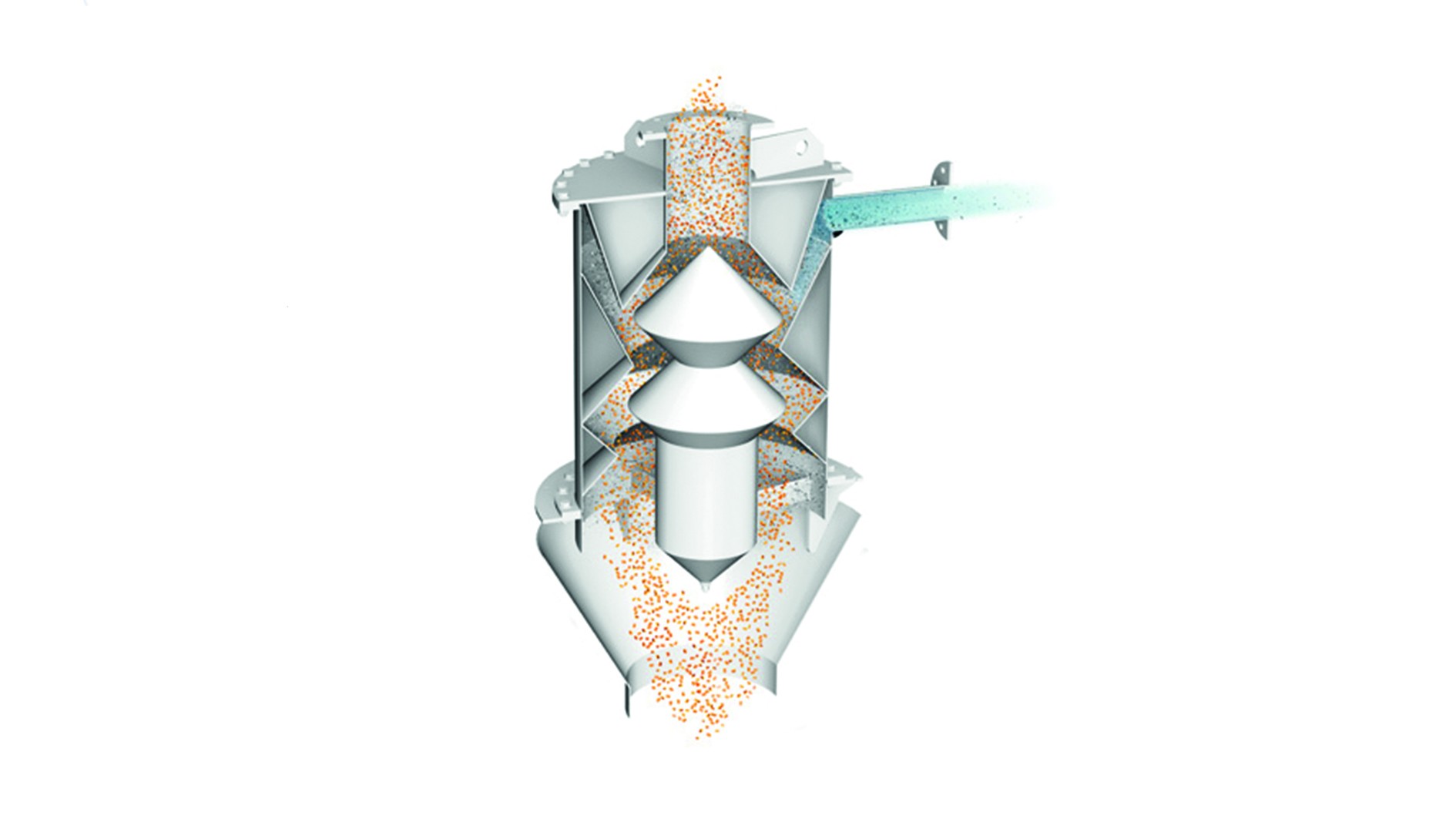

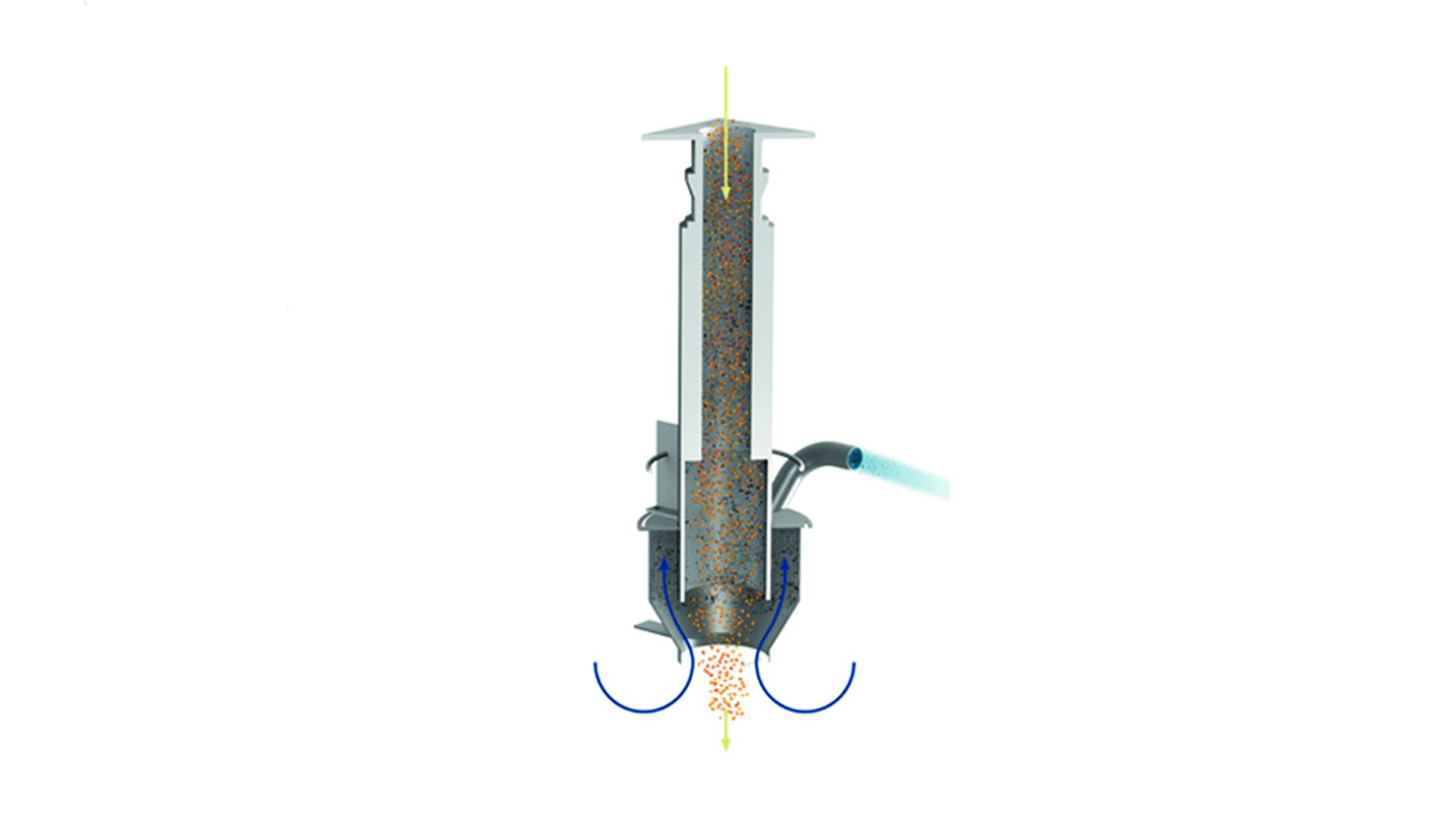

The VB vibratory bottom is used to activate bulk material flow for virtually all poorly-flowing, non-fluidizable bulk materials for discharge from silos and vessels. The vibratory bottom is used for external and internal storage silos as well as weighing and storage vessels. The output of a vibratory bottom cannot be metered or adjusted, so the vibratory bottom acts solely as a discharge device. A downstream rotary feeder would serve as a dosing device. Characteristics: Discharge bottom for activation of bulk material, functioning on the principle of vibration. Funnel output bottom with welded-in relief cone, firmly attached unbalanced motor and vertical buffering suspension rings form a sturdy unit, which ensures the uniform discharge of the dynamic loads Universally suitable for virtually all bulk materials without modification The sleeve on the product feed area decouples vibrations from the silo or vessel. The product discharge area is connected to a downstream unit by means of a sleeve and connecting nozzles. This connects to the vibratory bottom at the top and base, creating a tight, closed and freely vibrating system. Effective lines of force are created by uniform vibration input via a support ring. The vertical buffering suspension rings support the vibratory bottom and ensure the statically required load absorption and the precise recovery of horizontal loads. Integrated emergency slide valve for use in emergencies, e.g. removal of downstream unit when silo is full Long lifespan and low maintenance outlay Vibratory bottoms are attached to the silo or vessel by means of a bored support ring (mating flange). Optimal discharge capacity thanks to two outlet sizes: 180 and 250. Made from 1.4307 stainless steel Temperature resistance between -10° and 80°C (operational and mechanical design temperature) ATEX-compliant Equipment configurations, options and accessories: Vibratory hopper without relief cone Hygienic, non-retracting C-sleeve made from a woven composite material Explosion-proof up to 1.5 bar (g) Vibratory bottom connection kit Connecting nozzle to downstream unit Support bracket for mounting to unit

About the Zeppelin

You can contact us for all products of the brand Zeppelin. We will send you a special offer as soon as possible!